Scientists from around the world are working to make prosthetics more responsive, more life-like, and more affordable. Combined, these developments hold great promise for amputees.

Argentine Company Combines Fashion and Finesse in New Prosthetic Hand

Argentina-based Bioparx Health Technology has produced the first prosthetic arm fully developed and manufactured in Latin America. The new prosthesis is fitted with sensors that detect and respond to an amputee’s nerve impulses, giving users more control than ever before.

Once the stuff of sci-fi movies and superheroes, digital sensors and new, lighter plastics are making bionic limbs possible for amputees around the world. The Latin American prosthesis costs less than half of the traditional replacement hand.

The Bioparx prosthetic hand has two parts. A bionic-like skeleton made from flexible plastic—with a clawlike hand with movable thumb, index and middle fingers giving the prosthetic its function. Then, a life-like glove fits over the entire prosthesis, allowing wearers to look their best while performing everyday tasks that require finesse—such as washing dishes or handwriting. The glove is washable, and can sport jewelry and even fingernail polish.

Bioparx’s prosthesis is part of a global movement to integrate digital sensors and light-weight, affordable materials into prosthetics design. Some companies are experimenting with 3D printers to design extremely lightweight and highly stylized limbs based on prints of the amputee’s anatomy. However, unlike the Bioparx prosthesis, most are not yet ready for use.

Bi-Directional Feedback Gives Amputees More Precision with Less Effort

At Chalmers University of Technology in Gothenburg, Sweden, scientists have successfully implanted a robotic prosthetic arm into one Swedish amputee. Anchored to remaining bone, electrodes are attached to the muscles and nerves themselves for increased two-directional feedback. Messages go from the prosthesis to the brain and from the brain to the prosthesis.

This technology, according to Chalmers research scientist Max Ortiz Catalan, is

“an important step toward more natural control of artificial limbs. It is the missing link for allowing sophisticated neural interfaces to control sophisticated prostheses. So far, this has only been possible in short experiments within controlled environments."

Silicon Skin-Like Covering that Looks and Feels Like the Real Thing

Researchers in South Korea have created a skin-like prosthetic covering from ultra-thin silicon. The product incorporates pressure, temperature, and humidity sensors for nerve stimulation and is capable of facilitating highly localized skin-like responses to external stimuli.

The sensing silicon skin is fully operational even when stretched more than 30%, so a user would not lose functionality by flexing a wrist or shaking hands. Although still in development, this research suggests the possibility of sensing external stimuli through devices covered in this prosthetic skin.

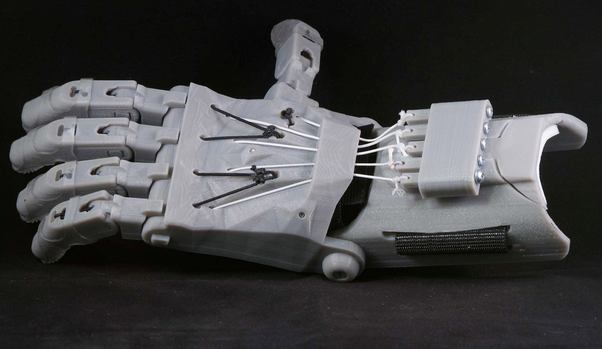

Open-Source Design for 3D Printable Prosthetics

e-NABLE is a non-profit organization founded by an American prop maker and a South African carpenter to create open-source designs for mechanical hand-like devices that can be downloaded and printed for less than $50 in materials. The organization has grown from two relatively average men who wanted to help a child in need to include engineers, scientists, artists, philanthropists, occupational therapists and the like from around the world.

3D printed plastic is somewhat brittle; therefore, the 3D printed prostheses are not as durable as others on the market. They are, however, an inexpensive alternative especially suited to young children whose rapid rate of growth or rough play might otherwise prohibit the use of prosthetic devices. 3D printed prosthetic limbs can also be worn in water, enabling a user to build confidence and independence by showering or swimming unhindered.

The Raptor Hand - Source: e-nablingthefuture.org (CC)

At a recent conference, Dr. Albert Chi, a trauma surgeon at Johns Hopkins and prosthetics researcher, said:

“e-NABLE’s collaborative approach to design and democratization of 3D-printed prostheses could significantly improve millions of lives worldwide. Now is the time to bring these technologies and practices into mainstream medicine.”

Jenn Lonzer has a B.A. in English from Cleveland State University and an M.A. in Health Communication from Johns Hopkins University. Passionate about access to care and social justice issues, Jenn writes on global digital health developments, research, and trends. Follow Jenn on Twitter @jnnprater3.